R&R-BETH®wet, tar and oil mist electrostatic precipitators are used for cleaning exhaust air processes containing aerosols, where the use of a dry separation process is not possible due to the dust and gas characteristics.

For decades, this technology has been used and optimized by R&R-BETH®to reliably filter aerosols with the finest dust particles as well as water-saturated process gases containing tar and oil.

Another positive effect is the additional separation of pollutant components such as HCl, SO2, NaCl and HF.

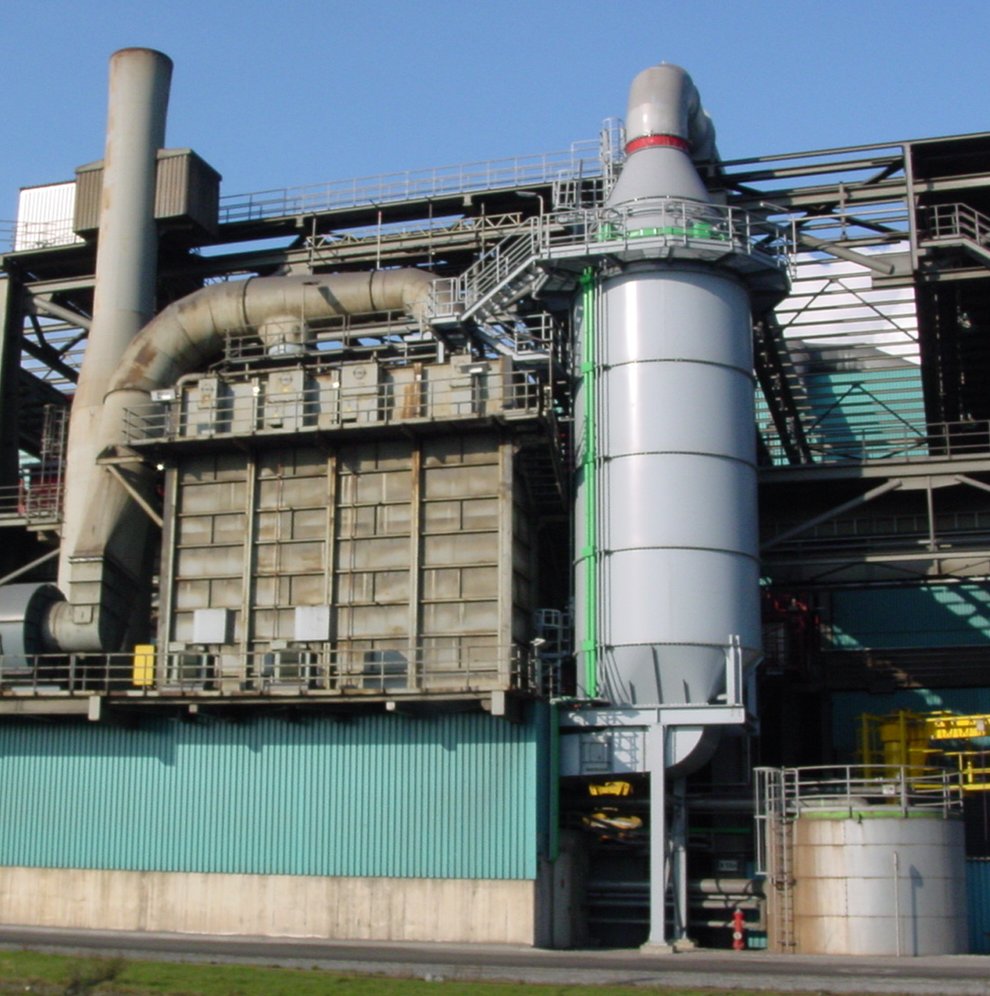

R&R-BETH®wet electrostatic precipitators are mostly used for cleaning process gas streams downstream of dryers, scrubbers or quenchers.

R&R-BETH®tar electrostatic precipitators are mainly used in the process cleaning of charcoal works.

R&R-BETH®oil mist electrostatic precipitators are used for cleaning aerosols containing oil (e.g. oil mist and oil vapors).

FUNCTIONAL PRINCIPLE

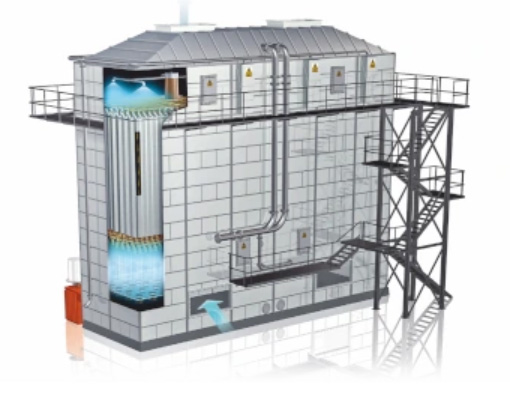

The process gas enters the electrostatic precipitator vertically from below and is brought to a uniform flow profile across the entire filter cross-section by means of gas distribution.

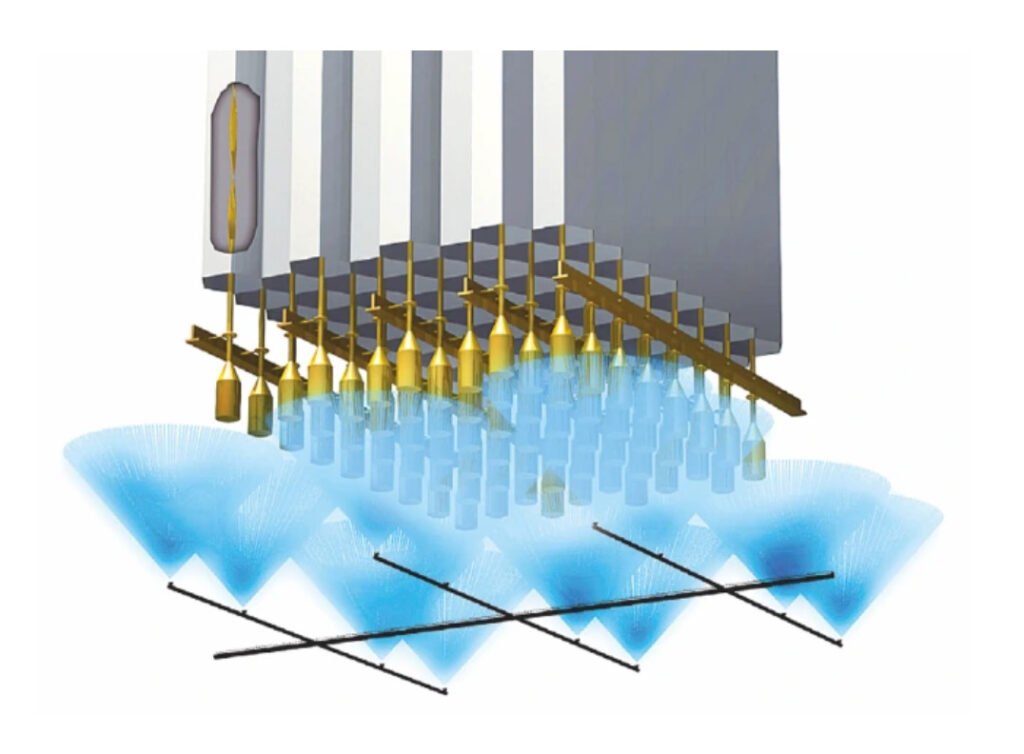

The particles or aerosols / water droplets are electrically charged by the high voltage (78-135 kV) applied between the spray electrodes and the precipitation honeycombs.

On their way through the electric field, the charged particles are transported by the electrostatic field forces to the collecting electrodes, where they agglomerate with the already deposited particles and are cleaned off by periodic use of rinsing water.

The dust/water mixture flows automatically into the filter tray located below the gas inlet. The cleaned gas leaves the filter through the gas outlet hood located on the filter head.

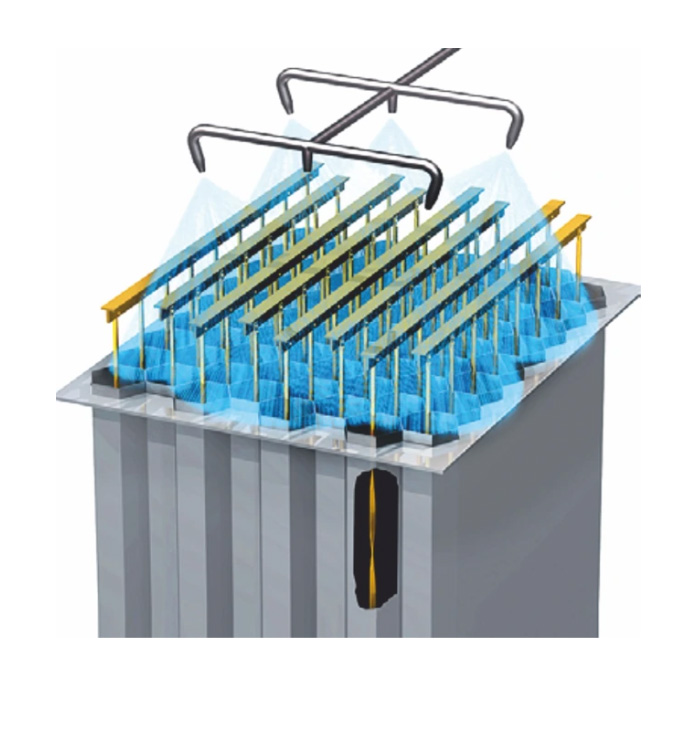

Gas conditioning by continuous injection of fog water (arranged between gas distribution and electric field)

Cleaning of the honeycomb-shaped collecting electrodes and the spray electrodes by a periodically acting rinsing water system