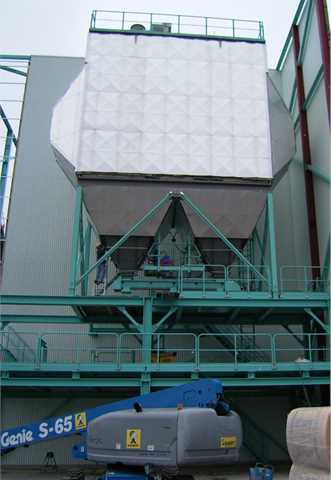

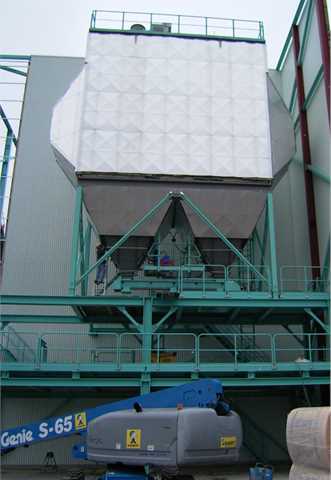

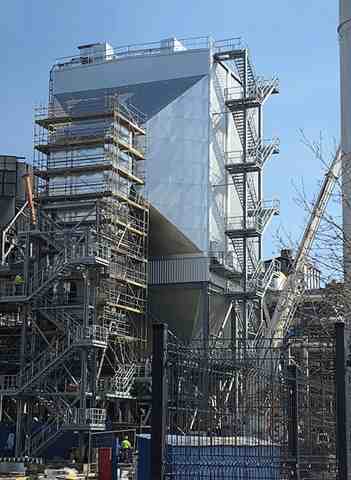

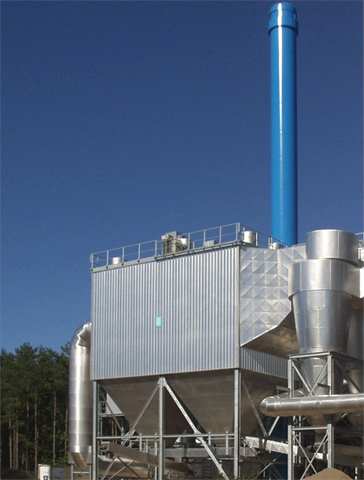

R&R-BETH®dry electrostatic precipitators separate the finest dust particles from process air and exhaust gas flows with temperatures of up to 420 °C.

This filter technology is mainly used for hot gas dedusting in incineration plants or drying processes with hot gas applications.

Artificial electrical charging separates the finest dust particles from the exhaust gas flow.

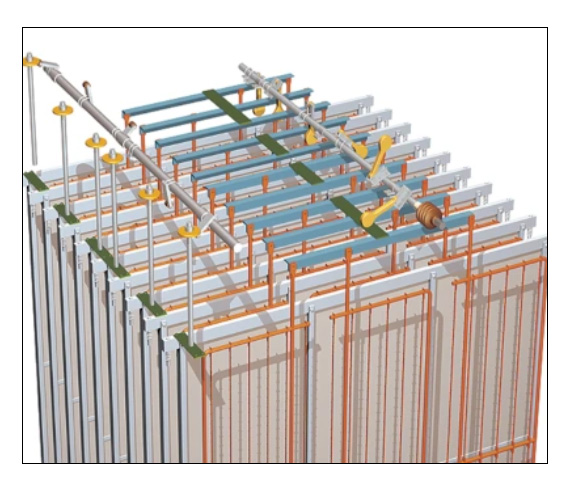

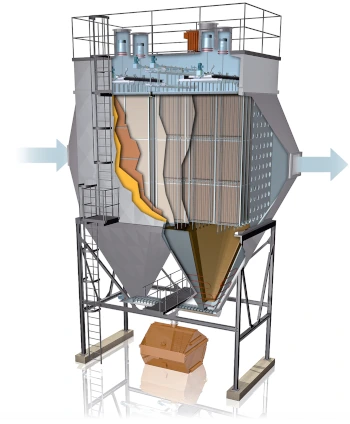

A modular system, which includes various housing sizes, aisle spacings and removal systems, enables the system size of the R&R-BETH®dry electrostatic precipitators to be adapted to the process specifications of our customers.

This means that reliable cleaning of volume flows of up to 1,000,000 Bm3/h can be achieved.

Thanks to innovative solutions, we are able to safely achieve clean gas values of 5 mg/m3 residual dust with the R&R-BETH®dry electrostatic precipitator systems.

Functional principle

The dust-laden process gas enters the electrostatic precipitator horizontally and is brought to a uniform flow profile across the entire filter cross-section by means of gas distribution.

An electric field is generated by the spray electrodes arranged between the collecting plates by means of high voltage and the dust particles are electrically charged. On their way through the electric field, the charged particles are transported to the collecting electrodes by the electric field forces, where they agglomerate with the already deposited dust particles and are cleaned by the knock-off devices.

The knocked-off dust layer falls into the filter hopper and is discharged via the dust outlet. The cleaned gas leaves the filter through the gas outlet hood.

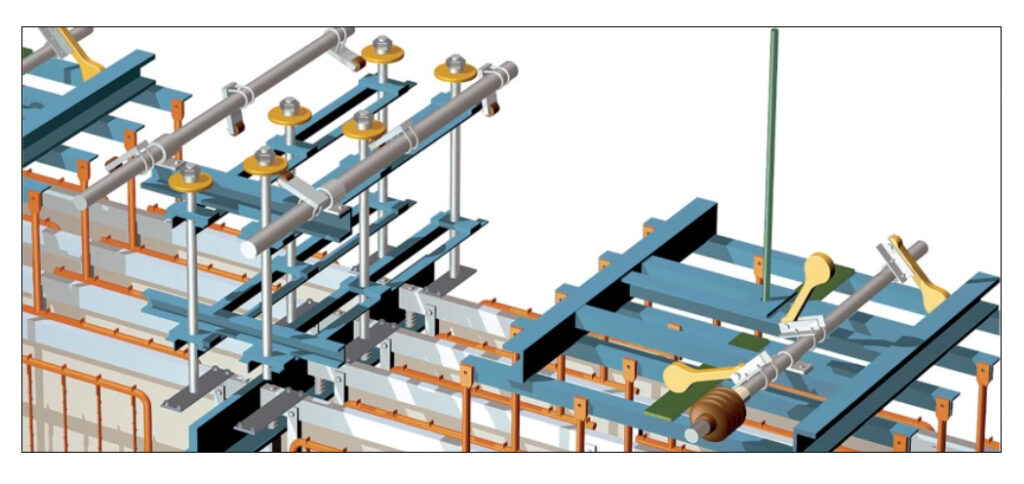

Precipitation and spray electrode rapping. The spray and collecting electrodes are cleaned by periodically acting, motor-driven knocking systems.

Electric spray system (gas cleaning zone)