The energy industry is currently undergoing a huge transformation process worldwide due to the move away from the use of fossil fuels. In recent years, innovations have multiplied in the areas of using previously unused energy sources, improving emission values and expanding process chains for the direct use of energy. This exciting environment offers the “researchers and developers” of the R&R Group plenty of material for the development of new technologies, processes and products. Together with research partners, our research and development team has found a way to separate CO2 from industrial waste gases and make it available as a raw material in its purest form.

Our extraordinarily wide range of products includes:

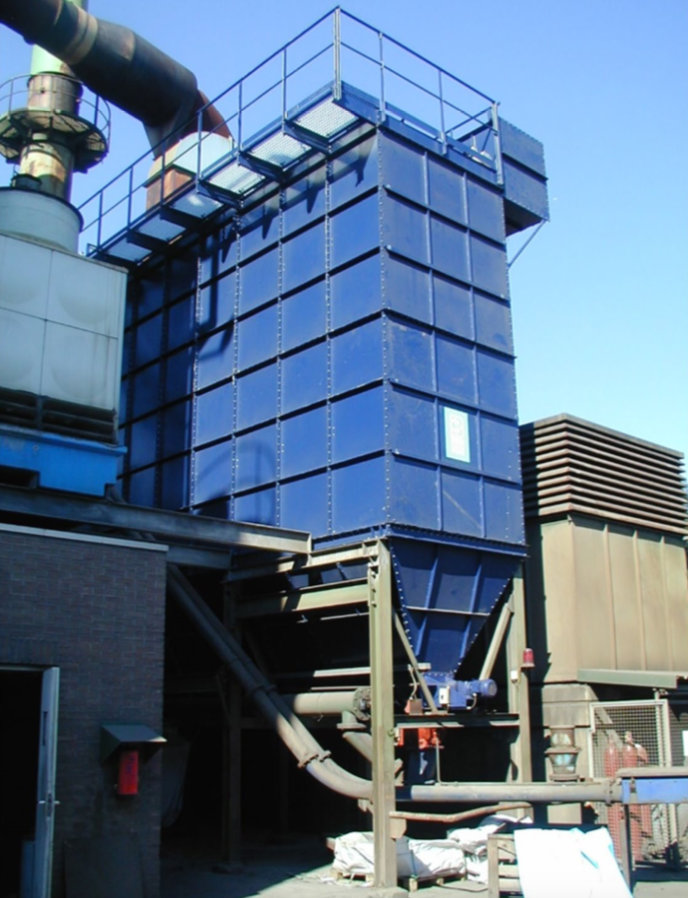

- Bag filters

- Dry electrostatic precipitators

- Wet electrostatic precipitators

- Pipe and duct components

- Additive feeders

- Silos

- Flue gas stacks

- Noise protection devices

- Container loading

- High-pressure transport systems

- fire protection systems and versatile individual units and assemblies from the R&R Group.

Process extraction of an exhaust gas cleaning system for hazardous waste incineration

Volume flow: 82,000 Bm3/h

Operating temperature: 150°C

Dust separation

Gas purification

Sulphur oxides (SO2)

Hydrogen chloride & hydrogen fluoride (HCL, HF)

PCDD/PCDF, Germany

Exhaust gas cleaning for hazardous waste incineration

– Volume flow: 82,000 Bm3/h

– Operating temperature: 150 °C

– Dust separation

– Gas purification of

– Sulphur oxides (SO2)

– Hydrogen chloride (HCl)

– Hydrogen fluoride (HF)

– PCDD / PCDF

Germany

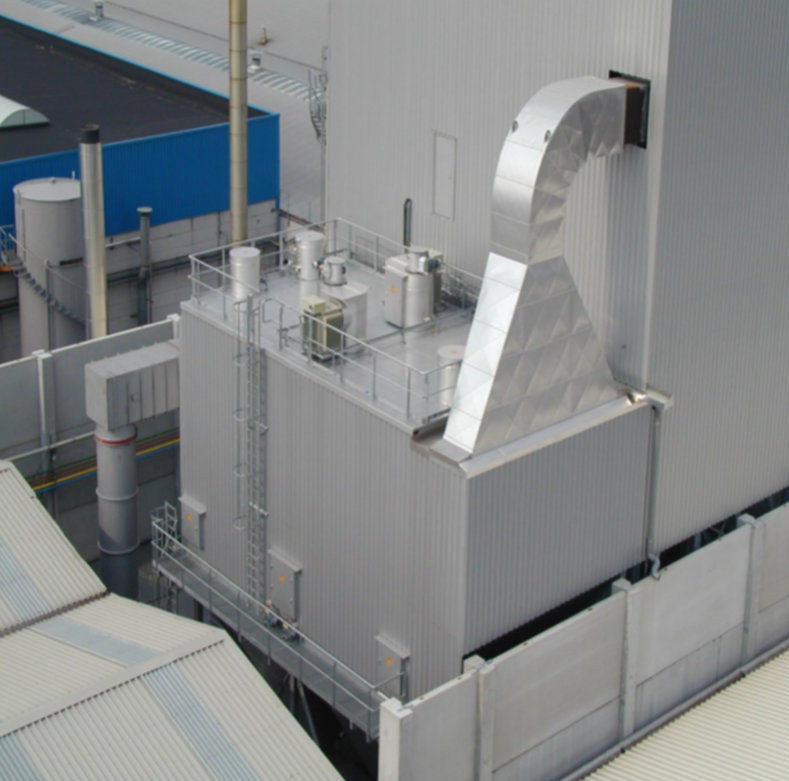

Flue gas cleaning for a waste-to-energy plant

– Volume flow: 154,600 Bm3/h

– Operating temperature: 120°C Dew point <100°C

– Dust separation

– Gas cleaning of:

– Sulphur oxides (SO2)

– Hydrogen chloride (HCl)

– Hydrogen fluoride (HF)

– PCDD / PCDF

Germany

Waste gas purification for sewage sludge incineration

– Volume flow: 27,000 Bm3/h

– Operating temperature: 134°C

– Dust separation

– Gas purification of

– Sulphur oxides (SO2)

– Hydrogen chloride (HCl)

– Hydrogen fluoride (HF)

– PCDD / PCDF

– Mercury

Germany

Bag filter systems and biofilters

Delivery hall

Deep bunker facility

Waste treatment

Volume flow: 170,500 Bm3/h

Dust separation

Odor cleaning

Austria

Dedusting of a waste treatment plant

Volume flow: 165,000 Bm3/h

Soundproof housing for fans and changeover dampers

Explosion protection: chem.

Ex suppression and bursting disks

Germany

Process extraction of biomass combustion

Fuel: wood chips, bark, shavings

– Volume flow: 86,600 Bm3/h

– Design temperature: 250°C

– Design pressure: approx. 35mbar

– Dust separation

Estonia

Process extraction of biomass combustion

– Volume flow: 88,971 Bm3/h (normal) / 98,116 Bm3/h (boiler cleaning)

– Residual dust content: <10 mg/m3

– Temperature (design): 250°C

– Pressure (design): Approx. 50 mbar

– Dust separation

Scotland

Process extraction of biomass combustion

– Fuel: wood chips, shavings, dust

– Volume flow: 28,340 Bm3/h

– Design temperature: 250°C

– Design pressure: approx. 25hPA

– Dust separation

– Exhaust air chimney

France

Process extraction of biomass combustion

– Fuel: Wood residues, plant residues from tomato cultivation

– Volume flow: 58,000 Bm3/h

– Temperature (design): 250 °C

– Pressure (design): Approx. 25 mbar

– Dust separation

– Exhaust air chimney at the filter

Netherlands

Process extraction of biomass combustion

– Fuel: wood chips, bark, shavings

– Volume flow: 98,940 Bm3/h

– Design temperature: 250 °C

– Dust separation

– Installation of the filter on an on-site concrete ash storage silo

Germany

Process extraction of biomass combustion

– Fuel: wood chips, bark, shavings

– Volume flow: 58,000 BM3/h

– 1,780 mg/Nm3 < 5 mg/Nm3 at 6% O2

– Dust separation

Netherlands

Process extraction of biomass combustion

– Volume flow: 128,000 Bm3/h

– 2,200 mg/Nm3 – 20mg/Nm3 at 400°C

– Dust separation

Belgium

Process extraction of biomass combustion

– Volume flow: 95,700 Bm3/h

– 4,500mg/Nm3 – <20mg/NM3 at 170°C

– Dust separation

– Cyclone separator

Germany

Process extraction of biomass combustion

– Fuel: wood chips, bark, shavings

– Volume flow: 735,000 Bm3/h

– 500 mg/Nm3 – < 10mg/Nm3

– Dust separation

– Regulation, control, electrical installation

Poland

Process extraction of biomass combustion

– Fuel: wood chips, bark, shavings

– Volume flow: 735,000 Bm3/h

– 500 mg/Nm3 – <10mg/Nm3

– Dust separation

– Control

– Control

– Electrical installation

Poland

Process extraction of biomass combustion

– Fuel: wood chips, bark, shavings

– Volume flow: 735,000 Bm3/h

– 500mg/Nm3 – < 5mg/Nm3

– Dust separation

– Control

– Control

– Electrical installation

Hungary

Process gas pipeline for fly ash downstream of a rotary kiln system

– Volume flow (hot gas extraction): 35,000 Bm3/h

– Diameter: 1,200mm (incl. 250mm inner lining)

– Temperature: max.

1,100°C

– Diameter: 760mm

– Temperature: max.

450°C

Germany

Flue gas pipe incl.

Pipes, bends, transitions and fittings

– Material S235JR

– Max.

Operating temp.

up to 230°C

– Special approval by TÜV as these components are used in a building in overpressure operation (risk of poisoning and suffocation)

Czech republic

Special piping system with unsupported span of up to 35m

– Volume flow: 90,000 Bm3/h

– Material thickness: -14 mm

– Diameter: 1,200 mm

– Total length: 520 m

– Distance between support points 35 m (self-supporting pipe system)

Germany

Hot gas cyclone

– Separation of fly ash after a rotary kiln

– Volume flow: 35,000 Bm3/h

– Temperature: max.

1,100°C

– Fireclay lining

– Special insulation

Germany

Exhaust air chimney

– with working platform, painted according to customer requirements, with verifiable statics, – complete assembly

Height: according to customer requirements

Germany

Waste gas cleaning in a sewage sludge incinerator

– Spark separation

– Dust separation

– Recovery of phosphorus (P)

– Gas purification of:

– Sulphur oxides (SO2)

– Hydrogen chloride (HCl)

– Hydrogen fluoride (HF)

– Heavy metals

Germany